Seal of Recommendation

Safe & Effective Sun Protection

The Skin Cancer Foundation Seal of Recommendation is a symbol of safe and effective sun protection that is recognized and trusted by consumers worldwide. Created in 1981, the Seal of Recommendation is an important resource that you can rely on to help you make the best decisions when choosing sun protection.

Seek the Seal!

Seek the Seal!

You can find the Seal of Recommendation on all types of sun protection products, including sunscreen, UV-protective fabric, window film and tint for home and cars, outdoor shade, hats and UV-protective eye and sunglass lenses. When you choose a product with the Seal of Recommendation, you’ll have the peace of mind knowing that you’re choosing the highest standard of sun protection. See for yourself! Search our Recommended Products.

Seal of Recommendation FAQs

What is the Seal of Recommendation?

The Seal of Recommendation is a badge displayed on the products that The Skin Cancer Foundation recommends for safe and effective sun protection. When used as directed, these products will help protect your skin from sun damage that can lead to skin cancer.

What are the requirements for sunscreen products to earn the Seal of Recommendation?

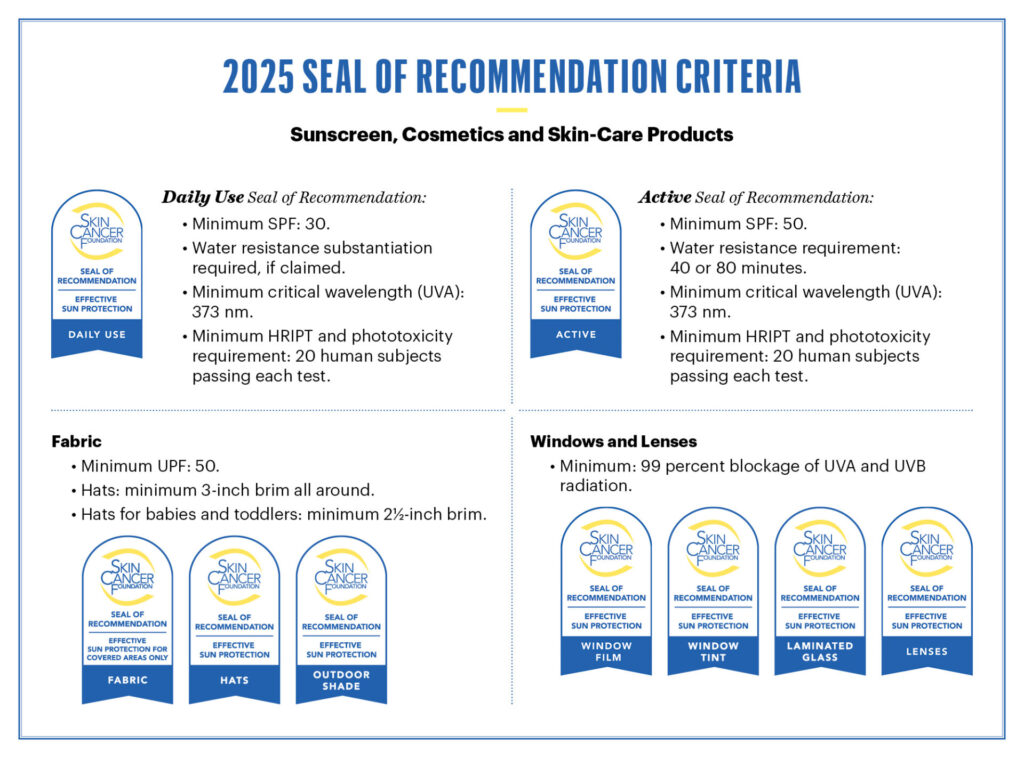

Daily Use Sunscreen Seal of Recommendation Requirements:

Daily Use Sunscreen Seal of Recommendation Requirements:

Minimum SPF of 30 and substantiation of any water-resistance claims.

Minimum critical wavelength (UVA) 373 nm.

Passing phototoxicity and HRIPT tests.

Active Use Sunscreen Seal of Recommendation Requirements:

Active Use Sunscreen Seal of Recommendation Requirements:

Minimum SPF of 50 and proof of water-resistance for 40 or 80 minutes.

Minimum critical wavelength (UVA) 373 nm.

Passing phototoxicity and HRIPT tests.

What are the requirements for hats and fabric used in apparel and shade products to earn the Seal of Recommendation?

Fabrics and Hats: You can find the Seal of Recommendation on products made with UV-protective fabrics, including awnings, umbrellas, clothing, accessories and hats.

Fabric requirements: Minimum UPF 50.

Hat requirements: Adult hats must have a minimum 3-inch brim around the circumference or a minimum 3-inch bill with a permanently attached drape to cover the neck and ears. Baby and toddler (under size 5T) hats must have a minimum 2½-inch brim around the circumference.

What are the requirements for window film, window tint, lenses and glass to earn the Seal of Recommendation?

Window Film, Window Tint, Lenses and Glass: You can find the Seal of Recommendation on automobile window tint, architectural window film, laminated glass and lenses in sun and eyeglasses.

Requirements: The product must block 99 percent or more of UVA and UVB radiation.

Where can I find products with the Seal of Recommendation?

Everywhere! From your favorite big box store to a boutique resort shop and even at your local window tinter. There are currently more than 800 products worldwide that have earned The Skin Cancer Foundation Seal of Recommendation for safe and effective sun protection.

You can see the Seal displayed on hangtags, labels and packages in stores. If you shop online, you’ll find that many products include the Seal of Recommendation on product details pages. Note that not all products display the Seal of Recommendation on their packaging so check our list of Recommended Products to see them all.

Can I see a list of products that have earned the Seal of Recommendation?

Visit our Recommended Products page to see all the products that have earned the Seal of Recommendation. You can also try out our Sun Protection Product Finder to find products that are right for you!

How does a product earn the Seal of Recommendation?

Companies submit an online application that includes results from scientific tests that substantiate the sun protection and safety claims of their product(s). Our Photobiology Committee reviews each submission to confirm that every product meets our requirements and, if so, the product earns the Seal of Recommendation.

What is the Photobiology Committee?

The Skin Cancer Foundation’s Photobiology Committee is a group of dermatologists who are experts in the study of the interaction of UV radiation and the skin. These dermatologists generously volunteer their time to guide the Foundation in establishing the requirements to earn the Seal of Recommendation. Each Seal application is reviewed by the Committee to ensure that the product meets the requirements to earn the Seal. The committee’s expertise and credibility make the Seal of Recommendation a trusted and valuable resource for consumers.

Program Eligibility

Members of The Skin Cancer Foundation’s Corporate Council who manufacture or market sun protection products are eligible to earn the Seal of Recommendation. Companies representing more than 100 brands support the Foundation’s mission with an annual Corporate Council membership fee of $15,000. Corporate Council membership fees help support our education programs.

To apply, manufacturers complete an application and submit required product data and testing results, which are reviewed by our volunteer Photobiology Committee. Not all of a Corporate Council member’s products meet our standards, and not all submitted products are approved. The Seal of Recommendation is granted to individual sun protection products, not to brands.

As of September 1, 2024 we have increased the minimum required criteria for the Seal of Recommendation. This criteria is reflected above. We will continue to accept previous criteria through June 1, 2025. Please contact [email protected] with any questions or for additional information.

If you are interested in learning more about the Seal of Recommendation, please contact [email protected].